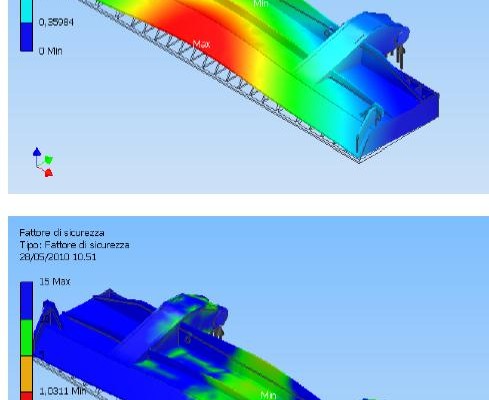

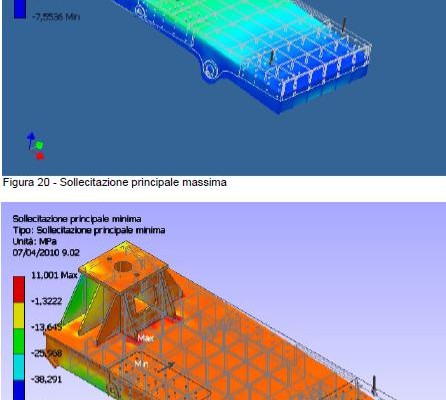

STRUCTURAL VERIFICATION WITH FEM ANALYSIS

FEM structural analysis is a fundamental tool for mechanical design and for tackling and solving problems in machine building and structural mechanics. It is performed in order to verify, already at the design stage, the fulfilment of requirements and to assess the strenght and stability of a component or an entire machine or plant.

Safety and reliability are major concerns in the desing and development of machinery.

For particularly stressed parts and large structures whose failure could cause serious damage, structural calculations are performed using programmes based on the finite element analysis (FEM) methodology. This methodology allows a detailed understanding of the structural behaviour, even under extreme or unexpected loads, and to remove any risks by acting on the most stressed sections or, where this is problematic, by proposing alternative solutions.

Structural calculations are able to detect the vulnerabilities of a component or system and allow the degree of security and reliability to be assessed. To ensure compliance with these principles, structural calculations must be carried out accurately and must take into account the production processes, technologies and systems used.

In addition, structural analysis makes it possible to assess the deformations and stresses to which a component or system is subjected in order to ensure maximum efficiency and durability. For this reason, it is a crucial step in the mechanical design of machinery and plants.

Finally, structural calculations are also crucial for the assessment of risks and hazards associated with the use of machinery and plant. Safety is therefore a priority aspect in the design and development of machinery, and structural analysis is one of the main tools for ensuring reliability and safety.